Jinan, Shandong, China

Response Time: < 24h

Response Rate: 0%

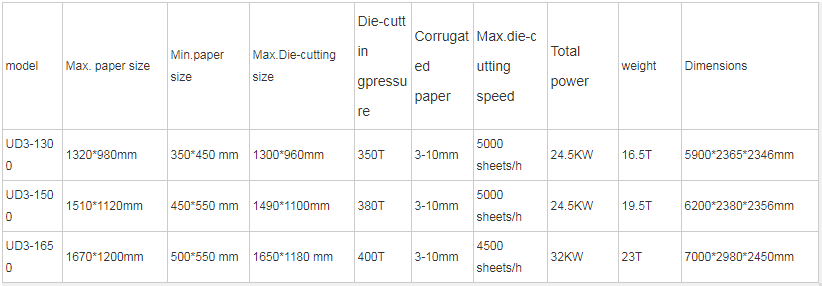

| Model No.: UD3-1300 | Brand: 泰瑞和/unicorn/睿尚嘉... | Place of Origin: China |

product description

Machine Introduction:

1. Equipped with pneumatic clutch and pneumatic locking plate.

2. Lead edge feeding paper. The high-speed and high precision paper feeding device can transmit all kinds of corrugated paper whenever how the quality of paper is. Equipped with light-adjusted device and has suitable ability.

3. Automatic adjusting paper feeding, paper collecting and paper aligning.

4.Automatic gripper type equipped the tooth row, open bite adjustable, under the help of paper, cardboard can run smoothly. Automatic suction suck about using leading edge of paper, tooth row gripper-style, curved cardboard and tissue paper can also be passed no scratches.

5. Pneumatic take samples when machine working, can check the die cutting effect at any time.

6. Dusting air guns, can effectively remove the template, and dust inside the device.

7. Automatic lubricating can add lubricating oil on the chain gear according to time, extended the working life of machine

8. Using alarm bells agencies in warning tone when the device is turned to raise safety warning.

9. Equipped with a precision of detection (Taiwan Riko) fiber optic switch, the paper is in place to detect and avoid paper waste.

Paper feeding unit

1.Adopt servo motor driver multi-axis no pressure feeding system, no mechanical transmission error.

2.Without full extension type paper glue of shaft transmission , implementation is true in the sense of zero damage,can prevent the deformation of cardboard an guarantee the accuracy of the paper.

3.Vacuum Suction lead edge feed and adjust the paper size as per pressure of wind.

4.Installing suck removing dust machine to eliminate the odd on the printing plate and improve the printing quality.

5.Non side breakage technology to decrease transmission difference to min degree.

6.Without equipping oil recycling and lubrication structure , and it is friendly to environment .

Die-cutting part and Delivery system

1.Die-cutting chase fixed accurately by pneumatic lock system

2. Die-cutting plate is putted in and out by air floating device

3.Electric clutch system of main chain can assure the chain steady when it is stopped at high speed

4.Main chain and assist chain is lubricated periodically controlled by PLC

5.Protection window of die-cutting can hold the main body clean

6. Lightweight and durable aluminum alloy 9-piece gripper bars with chain of Remold UK ensure accurate.

Packaging & Delivery

Packaging Details:

We usually packed this machine covered by plastic film.

Delivery Detail:

Within 30 days after we got the deposit.